Equipment and technologies for odour, VOC and corrosive gas testing

Instruments for odour laboratories, VOC emission testing and corrosive gas testing

As a manufacturer of olfactometers, VOC emission test chambers, corrosive gas test chambers, sampling equipment and software, we do everything we can for reliable and user-friendly odour, VOC and corrosive gas testing. Our complete solutions are field-tested in a variety of environments and optimally matched to each other. We are the only manufacturer, accredited testing laboratory and service provider for odour measurements in one. This is how we help you and your clients to become better. Day after day. Since 1996, worldwide. We do this through

- quick analysis processes

- immediate, tangible results

- measurement procedures conforming to standards and ready for accreditation

- optimised interfaces between human being and machine

- mobile application possibilities

- ergonomic designs

- and reliable support

Trust in the reliability and user know-how of the worldwide market leader!

Olfasense odour measurement equipment and techologies are solutions from users for users. Our expertise: More than 400 users of our technology worldwide, including research institutes, universities, odour laboratories and companies. Our claim: Maximum functionality, reliability and continuous development of odour measurement procedures and methods for

- equipping odour laboratories

- improved panel selection

- expansion of the scope

- accreditation and notification

Take advantage of the best odour measurement devices and technologies – worldwide

Olfactometers

Odour measurement equipment for direct and comparative evaluation

Sampling equipment

Software products

Ion mobility spectrometry instruments

Odour laboratory accessories

Characterize VOCs under precise test conditions with our highly accurate and affordable standardized solutions

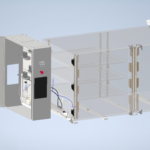

Single VOC emission test chambers

Multi VOC test chamber system

Customised chambers & accessories

Sophisticated corrosive gas testing according to different testing standards

Corrosive gas test chambers

Sniffing sticks & reference material

Sniffing sticks for panel selection

Sniffing sticks for odour characterisation

Sniffing sticks for odour intensity training

Customised sniffing sticks sets

VDA 270 training kits

Download our product catalogue

Client feedback

Take advantage of our service and support

Certified distributor network

Our certified distributors

FAQs - Frequently asked questions about olfactometry and odour testing

What is olfactometry?

The measurement of the concentration of odorous substances in an air sample is called olfactometry. In this sensory measurement method, the human nose is used as a “measurement device”. Test persons in olfactometry are also referred to as odour panellists. Several odour panellists for the analysis of an olfactometric evaluation form an odour panel.

How does olfactometry work?

In olfactometry, an odour sample, usually contained in a sample bag, is connected to an olfactometer. This device for measuring odours, first dilutes this odour sample with neutral-smelling compressed air so that the odour panellists do not perceive any odour. In each test round, the olfactometer dilutes the odour sample less until the odour panellists perceive the odour. This point of perception is known as the odour threshold. As a result, you now know the dilution ratio between neutral air and sample air. And you can determine the odour concentration in units of OU / m³ air. The olfactometry measurement method is standardized in the European standard EN 13725.

Where is olfactometry used?

Dynamic olfactometry standardized in accordance with the European standard EN 13725 is mainly used for odour measurements in the environmental sector to determine odours from an odour source, e.g. an industrial plant. For this purpose, samples are taken in sample bags e.g. from exhaust chimneys or from surface sources with special sampling devices. The samples are evaluated with a dilution device, the so-called olfactometer. Specially trained people, so-called odour panellists, are used as sensors. The results of an olfactometry can be used, for example, to determine which filter technology (e.g. biofilter, thermal post-combustion, activated carbon, etc.) should be used in order to reduce odour emissions in accordance with the regulatory requirements,.

How many odour panellists do I need to perform olfactometry?

The EN 13725 specifies that the minimum size of the odour panel must be at least 4 for each odour measurement. A larger number of odour panellists is recommended to improve repeatability and accuracy. About 80% of all professional EN 13725 laboratories worldwide work with 4-place olfactometers. Only in some countries like the Netherlands 6 odour panellists are required. Please note that you can also work with 8 or 6 odour panellists on a 4-place olfactometer by adapting the olfactometer software settings accordingly.

Can I also use so-called field olfactometers?

Olfactometers used outdoors, so-called field olfactometers, do not meet the technical requirements of the EN 13725, as odour panellists must be isolated from the outside air as described in Chapter 7.2.1. Many other factors make measurements with field olfactometers difficult and mean that the results of field olfactometers cannot be validated. For example, low odour concentrations are very difficult to measure. This means, there has to be a certain odour in the outside air in order to be able to measure at all with a field olfactometer. In addition, the EN 13725 describes the measurement of odour emissions “at the source”, which requires sampling directly from odour sources such as chimneys or biofilters. As a consequence, results from using field olfactometers cannot, strictly speaking, be presented in OU / m³. This makes it difficult to make reliable statements about possible degrees of odour reduction. There are also no well-founded studies on the precision and uncertainty of the measurement method using field olfactometers.