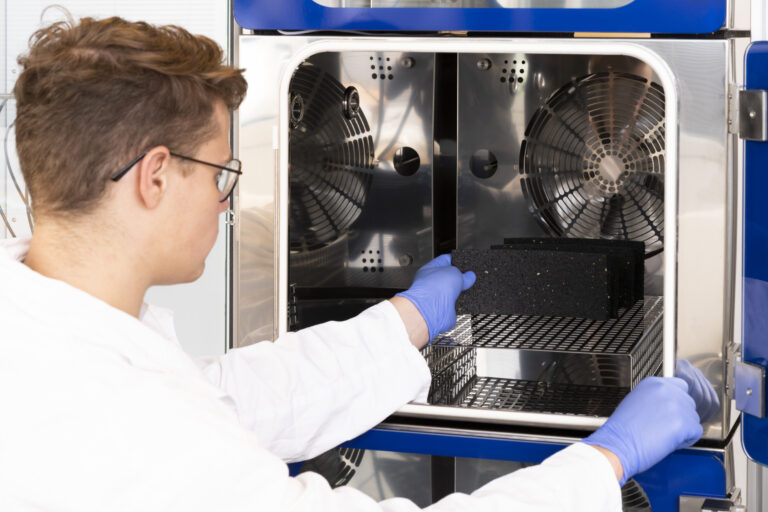

VOC emission test chamber with active temperature control

The Olfasense VOC emission test chamber with active temperature control allows characterization of the emissions of volatile organic compounds under precise test conditions.

The VOC emission test chamber is fully compliant with common European and international standards as well as specific automotive manufacturers’ standards.

The standard size of the chamber is 250l. Various other chamber volumes are optionally available.

For temperature control and thermal desorption, the VOC emission test chamber is built into a technologically advanced incubator from a well-known German manufacturer.

The chamber has been developed in close cooperation with experts from industry and research and can be used for a broad analytical performance spectrum via 4 heated sample ports.

Find out more below about how our VOC emission test chamber with active temperature control is used for highly accurate and affordable VOC chamber testing in different industry applications.

If you are looking for a VOC emission test chamber that can be used under general indoor air conditions, please check out our VOC emission test chamber with passive temperature control.

Specifications

- 250l VOC emission test chamber (225l, 240l, or other volumes optionally available)

- Compact, robust, competitively priced

- „Emission-free“ test chamber

- High accuracy and performance of all normative parameters

- Adjustable ventilation fan and (optional) hot-wire anemometer for optimized test specimen location

- Prevention of contamination from the surrounding environment

- Minimal adsorption effects

- Thermal desorption cleaning function up to 210°C

Chamber testing in the automotive industry

The quality of indoor air in vehicles is strongly influenced by volatile organic compounds (VOCs) released from components, semi-finished products and materials used in the vehicle interior.

The Olfasense VOC emission test chamber with active temperature control allows characterization of the emissions of volatile organic compounds from these materials under precise test conditions.

The chamber is fully compliant with the requirements of PV 3942 Volkswagen Method, GS97014-3 BMW Method and PN 780 Porsche Method. It meet also all requirements of ISO 12219-4 – with the exception of the chamber size.

Standard compliance

- Fully compliant with

- GS97014-3 BMW Method (Determination of VOCs from components, semifinished products and materials)

- PN 780 Porsche Method (Interieur – Emission behavior)

- PV 3942 Volkswagen Method (Determining organic emissions from components for the passenger compartment of motor vehicles. Emission test)

- Meets all requirements of ISO 12219-4 (Determination of VOCs from vehicle interior parts and materials ) – with the exception of the chamber size

If you have additional requirements, please ask for your tailormade product solution. In case your specific test method is not listed, our application experts will be happy to confirm if the chamber meets the requirements of your testing standard. Please contact us!

Chamber testing of combustible air fresheners

Combustible air fresheners, such as scented candles, are intended to enhance the odour quality of indoor air by releasing their fragrance aromas through the candle smoke. This may lead to an increased level of volatile organic compounds (VOC), which can influence the quality of indoor air.

The European Standard EN 16738 defines a test method for the determination of these VOC emissions from combustible air fresheners. The test method is based on the operation of an emission test chamber according to ISO 16000-9.

The Olfasense VOC emission test chamber with active temperature control allows characterization of the emissions of volatile organic compounds from combustible air fresheners under precise test conditions. The chamber is fully compliant with the requirements of ISO 16000-9 and EN 16738.

Standard compliance

Fully compliant with

- EN 16738 (Emission safety of combustible air fresheners – test methods)

- ISO 16000-9 (VOC emissions from building products and furnishing)

- EN 16516 (VOC emissions from construction products)

- GEV Testing Method (VOC emissions from products for flooring installation, adhesives, and building materials)

If you have additional requirements, please ask for your tailormade product solution. In case your specific test method is not listed, our application experts will be happy to confirm if the chamber meets the requirements of your testing standard. Please contact us!

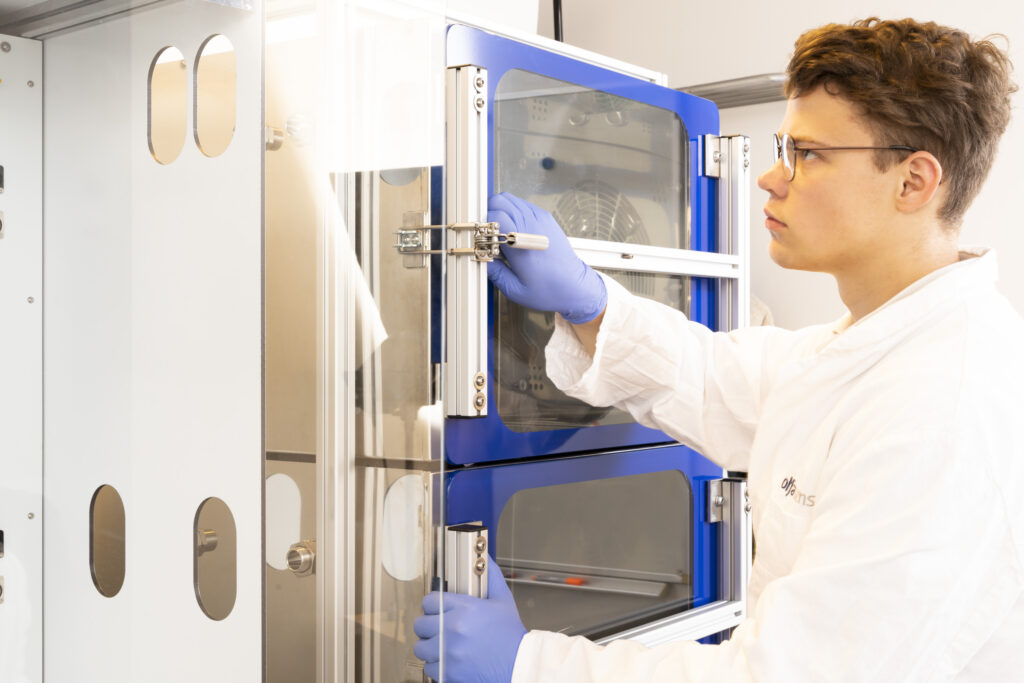

Optional extension with additional chambers

The Olfasense VOC emission test chambers are equipped with a universal base unit, which offers you the possibility to add additional chambers, also at a later stage.

This modular design allows you to configure your chamber solution individually, even if you decide to purchase only one chamber initially.

Please visit VOC emission test chamber system EK mRack or contact our experts via sales@olfasense.com to learn more about the features and benefits offered.

Additional images

Testimonials

Technical Data

1700 x 1550 x 1000 mm - size with incubator

612 x 832 x 1820 mm - size of base unit

140 kg - weight of base unit

(225l, 240l or other volumes optionally available)

CEE7 (230V 50Hz) - control unit

(other connections optionally available)