Ortelium – Real time dispersion modelling and odour impact analysis

Ortelium combines weather data feeds with the odour emission data from your plant’s odour sources. Calculating and dynamically visualizing the dispersion of your plant’s emissions on a digital map, Ortelium provides you with retrospective analysis, real-time monitoring and forecasting capabilities to model and monitor the odour impact of your operations in past, current and future situations.

This enables you not only to better understand and validate past incidents and their causes/origins. By forecasting possible impacts of your operations you can even take appropriate, proactive steps to avoid conflict situations, e.g. by finding the right window-of-opportunity to run odorous operations at times in which environmental impacts are minimized.

Specify the odour impact potential of your operations on your neighbourhood

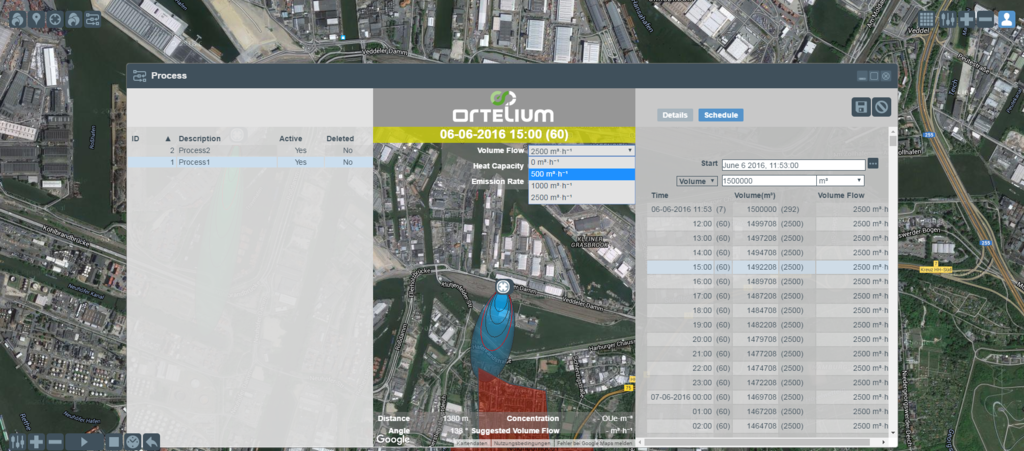

In Ortelium you can manage multiple odour sources and their processed substances by defining key parameters such as substance concentrations (OU/m³), source height and heat capacity, volume flows of your installations, as well as terrain roughness. You can also add information on your installation’s continuous and discontinuous processes by entering process schedules and process-specific parameters, for instance production capacities, start (and end) times.

By highlighting points or areas that are of special interest for your data monitoring (e.g.neighbouring residential areas, or other receptor points and areas) on the map, the module will instantly warn you if, and tell you how your site’s sources might impact these areas under the current and forthcoming weather conditions. In addition, the Ortelium timeline colour-coding provides instant information on odour-critical operation times, allowing you to proactively initiate appropriate actions to avoid potential incidents.

Choose the appropriate model for your purposes

Ortelium can be configured to use steady-state and non-steady-state dispersion models to offer the best-suited approach for each individual project. Ortelium’s Gaussian plume model can be fed with data provided by local weather stations or online feeds, while the Calpuff model is using high-resolution WRF data for the calculations.

In addition, Ortelium, provides full flexibility on emission source input data. Depending on the availability of the emission data the models can be fed with static emission source data or dynamic emission source data. Dynamic emission source data can be provided through sensor data feeds, if available, scheduled processes or schemas. This flexibility allows for continuous and discontinuous emission sources to be considered for modelling. The overall impact can be filtered for individual source contributions providing users with valuable insights about the most relevant sources.

If you are unsure about which model is the most appropriate model for your use case, our modelling experts will be happy to advise you on that decision.

Run your operations most efficiently while avoiding complaints

In case your emission process is stable and controllable, Ortelium provides recommendations on how to adapt your process parameters (such as pumping speeds or ventilation rates) during these odour-critical operation times, to reduce or even prevent alert situations, while keeping your operations running most efficiently. This is particularly useful for industries that are at risk of being panelized with temporary working restrictions, fines or in the worst case permit withdrawal.

Case Study

Vopak Terminal Europoort

Vopak Terminal Europoort is one of the biggest petroleum storage and transshipment facilities in the heavily populated Port of Rotterdam area. Oil gets loaded from the tankers to the storage tanks or vice versa, which results in the emission of high concentrations of odour that disperse into the surrounding residential areas.

Better grip on this dispersion is needed to avoid odour complaints, as these may result in temporary working restrictions, fines or in the worst case permit withdrawal.

By inserting process parameters of the operations into Ortelium, the system provides data intelligence on how the odour disperses into the environment. In case concentrations in residential areas are too high, Ortelium provides recommendations on how to adapt pumping speeds to reduce or even prevent the alert situation. Not only for the current point of time but also for the hours to come.

As a result, pumping processes keep running efficiently while odour complaints are avoided.

… pumping processes keep running efficiently while odour complaints are avoided.