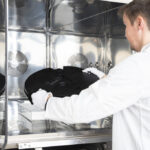

VOC test chamber EK1000

The quality of indoor air in vehicles is strongly influenced by volatile organic compounds (VOCs) released from components, semi-finished products and materials used in the vehicle interior.

The Olfasense 1 m³ VOC emission test chamber EK1000 allows characterization of the emissions of volatile organic compounds under precise test conditions, and is fully compliant with the requirements of ISO 12219-4 and VDA 276.

The chamber meets also all requirements of the manufacturer standardards GS97014-3 (BMW method), PN 780 (Porsche method), VCS 1027, 2769 (Volvo method), as well as PV 3942 (Volkswagen method).

The chamber is optionally available with a SHED function for testing according to GS-97014-2, as well as a fogging device according to VDA 276 and VCS 1027, 2769 (Volvo method).

The chamber has been developed as a joint venture with the company CTS, one of the leading specialists in the field of environmental simulation. Their innovative and technically high-quality products are delivered to the most renowned industrial companies worldwide, with more than 12,000 devices sold in Germany and abroad. Major client segments include the automotive industry and its suppliers, as well as test laboratories.

By consolidating their respective know-how and expertise, our two companies have developed the EK1000 VOC emission test chamber, providing clients a technically and economically optimized test system to characterize emissions of volatile organic compounds under precise test conditions.

Key facts

- Precise compliance with all method and measurement parameters

- Minimized adhesion

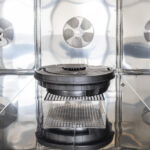

- Rotor with drive via non-contact magnetic coupling and emission-free ceramic bearings (speed adjustable)

- Control panel for setting, controlling, monitoring and recording the parameters: temperature, humidity, mass flow with export function on USB stick

- 4 heated sampling ports, for a broad analytical performance spectrum

- Easy to maintain, plug-and-play humidity control unit

Fully compliant with

- ISO 12219-4 (Determination of VOCs from vehicle interior parts and materials )

- VDA 276 (Determination of Organic substances as emitted from automotive interior products using a 1 m³ test chamber)

- GS97014-3 BMW Method (Determination of VOCs from components, semifinished products and materials)

- PN 780 Porsche Method (Interieur – Emission behavior)

- VCS 1027, 2769 Volvo Method (Determination of volatile organic substances from interior components/systems using a 1 m³ emission chamber)

- PV 3942 Volkswagen Method (Determining organic emissions from components for the passenger compartment of motor vehicles. Emission test)

Is your test method not listed? Our application experts will be happy to confirm if the EK1000 meets the requirements of your testing standard. Please contact us!

Optional

- SHED function for testing according to GS-97014-2 BMW Method (Emissions measurement in SHED chambers. Determination of volatile, organic emissions from components, semi-finished products and materials that do not carry fuel), as well as CARB regulations

- Fogging device according to VDA 276 and VCS 1027, 2769 Volvo Method

- ISO 16000-9 (VOC emissions from building products and furnishing)

- EN 16516 (VOC emissions from construction products)

- EN 717-1 (Formaldehyde emissions from wood-based panels)

- GEV – testing method (VOC emissions from products for flooring installation, adhesives and building materials)