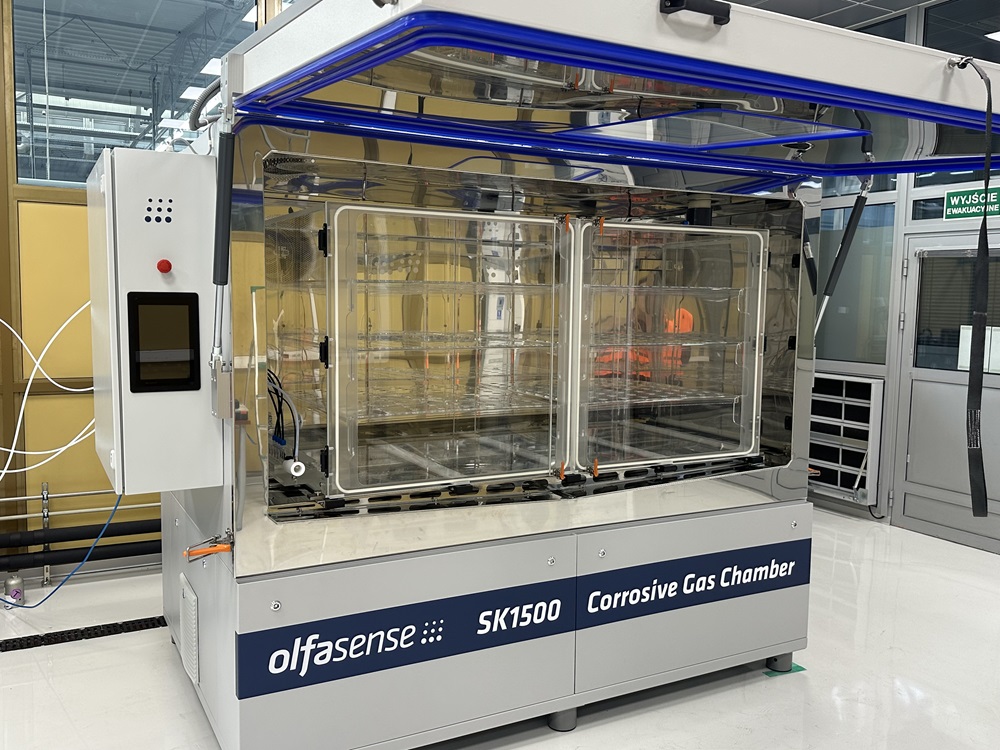

Corrosive gas test chamber SK1500

Pollutants in the atmosphere such as sulfur dioxide, hydrogen sulphide, nitrogen dioxide or chlorine gas can cause considerable corrosion damage to materials, components, assemblies, devices and buildings. Corrosive gas testing is crucial in the areas of research, design and quality assurance in order to assess the suitability and reliability of materials for specific applications and to prevent corrosion failure. To ensure comparable results, these tests are carried out according to different testing standards. Sophisticated corrosion testing systems are therefore essential for the systematic investigation of corrosion patterns (corrosion susceptibility/corrosion resistance).

Unique corrosive gas dosing system

Based on our extensive expertise in dynamic olfactometry and the resulting expertise in the mixing and dilution of gases, we have developed a unique corrosive gas dosing system.

This system enables extremely precise adjustment of the corrosive gas dosage, even at very low concentrations, and at the same time ensures ideal homogeneous mixing of the corrosive gases with the carrier gas.

At the same time, we have developed a specially designed user software to guide you through all standardised processes – entirely secure and uncomplicated.

It offers an intuitive user interface that guides you step by step through the entire corrosion testing process. This optimises your workflow and increases your efficiency.

Simultaneous dosing of up to 4 corrosive gases

With the SK1500 corrosive gas test chamber, we have successfully integrated this corrosive gas dosing system into a CTS climatic chamber to ensure standardised climate simulation and thus enable reproducible induction of corrosion. It is characterised by a removable container made of transparent, corrosion-resistant plastic (PMMA) and can be equipped with up to 4 individual dosing lines. This enables both corrosion testing with individual gases and the simultaneous dosing of up to 4 corrosive gases. The CTS climatic chamber can also be used flexibly for other tests by removing the PMMA container.

With a test volume of 1500 litres on up to 3 levels, the corrosive gas test chamber SK1500 is one of the largest corrosive gas test chambers on the market, allowing you to scale your corrosive gas measurements efficiently.

Our corrosive gas dosing system can be easily adapted and integrated into different climate chambers of various sizes. Thanks to this adaptability, we can offer you extremely versatile solutions that can be customised precisely to your specific requirements and the conditions of a wide range of test environments.

Key facts

- Ideal results thanks to high-precision corrosive gas dosing using a high-quality mass flow controller

- 100% homogeneous mixing of the corrosive gases before they enter the corrosive gas test chamber

- Regulation of the air exchange rate by means of a flow sensor at the inlet of the corrosive gas test chamber. This ensures correct concentrations in accordance with the corresponding standard when the corrosive gases enter the test chamber, preventing concentrations from increasing above the standard value.

- Software specially developed for the application of corrosive gas testing, which guides the user through the individual process steps in a user-friendly manner

- Clear view of the test material thanks to high-quality acrylic glass windows (polymethyl methacrylate) that enable transparent observation

- Compliance with industry-leading test standards such as IEC 60068-2-60, IEC 60068-2-42/43 and others to ensure reliable test results

Performance characteristics

- Possible test gases: hydrogen sulphide (H2S), sulphur dioxide (SO2), chlorine gas (Cl2) with carrier gas N2, nitrogen dioxide (NO2) with carrier gas synthetic air, and others

- Dosing of up to four corrosive gases with 4 corrosive gas dosing lines in the range 1-100 ml/min

- Pressure monitoring as an integrated safety device for reliable operation

- Connection for gas sampling for further analysis

- Testing of the corrosive gas concentration optionally possible with dry air or nitrogen

Testimonials

Technical Specifications

2200 x 1150 x 1100 mm (BxTxH)

1850 x 900 x 900 mm (BxTxH)